A valve stem is a small but vital part of your tire. It controls air flow during inflation and maintains tire pressure when driving. When it leaks or clogs, it can lead to a slow air loss, poor fuel economy, and even tire blowouts. The good news? Yes, a valve stem can often be fixed—even by yourself.

In this post, you’ll learn:

- Whether valve stems can be fixed

- How to replace a valve stem without removing the tire

- The total DIY cost

- If it’s safe to drive with a leaking valve

- How to clean a clogged valve

- Special tips for tubeless tires

Find tyre stem repair kit – Amazon

✅ Can a Valve Stem Be Fixed?

Yes, but it depends on the type of problem.

🔹 1. Leaky Valve Core

The valve core is a small part inside the valve stem that regulates airflow. It’s one of the most common causes of air leaks. It may loosen, corrode, or wear out—but it’s easily replaceable using a valve core tool.

🔹 2. Damaged Rubber Stem

If the rubber stem itself is cracked, dry, or cut, it’s time for a full replacement. This requires a bit more effort but is still manageable for DIYers.

🔹 3. Clogged Valve Stem

Sometimes, debris or liquid sealant can clog the valve. This may make inflation difficult or cause slow leaks. The stem may be cleanable or might need to be swapped out.

💰 DIY Valve Stem Repair Cost

Here’s a breakdown of typical repair items:

| Item | Estimated Cost (USD) |

|---|---|

| Valve stem replacement tool | $5 – $15 |

| New valve stem (rubber/metal) | $2 – $10 each |

| Valve core tool | $1 – $5 |

| Air compressor or inflator | $0 (if already owned) |

| Total (DIY) | $8 – $25 |

In India, expect to spend around ₹200 to ₹700 depending on the tools you already own.

Find tyre stem repair kit – Amazon

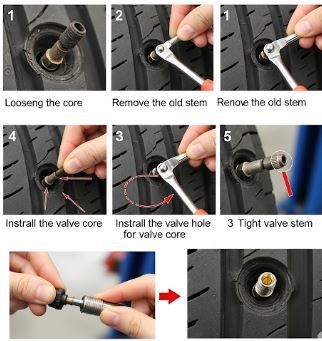

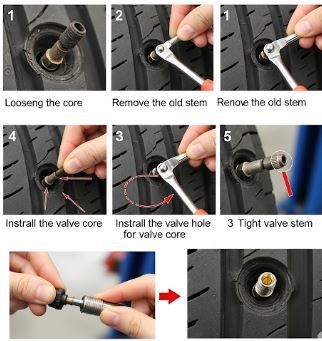

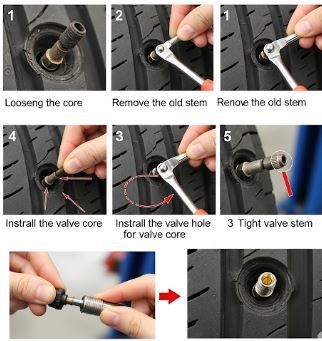

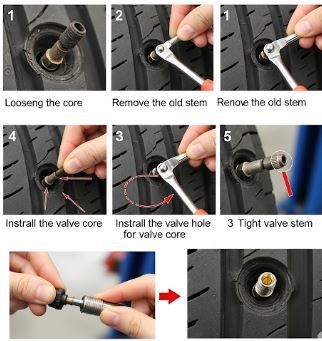

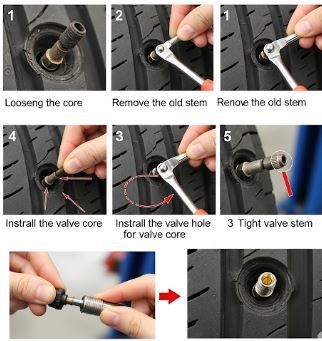

🔧 How to Replace a Valve Stem Without Removing the Tire

Although it’s best to remove the tire entirely, you can replace the valve stem without full removal if you break the bead on one side. This method is commonly used for tubeless tires.

📋 Steps:

- Deflate the tire by removing the valve core using a valve core tool.

- Break the bead near the valve stem using a C-clamp, tire irons, or bead breaker tool.

- Remove the old stem with pliers or cut it out.

- Lubricate the new stem using soapy water or tire lube.

- Insert the new valve stem through the rim hole and pull it through using a valve stem installer tool.

- Re-seat the tire bead using an air compressor or high-pressure air burst.

- Reinstall the valve core and inflate the tire to the recommended PSI.

- Check for leaks using soapy water.

⚠️ Note: If your valve stem is metal or part of a TPMS system, full tire removal is usually required.

🚗 Is It Safe to Drive with a Leaky Valve Stem?

No, it’s not safe to drive with a leaky valve stem. Here’s why:

❌ Risks:

- Air Loss: Leads to low tire pressure

- Reduced Traction: Compromised handling and braking

- Uneven Wear: Tires wear faster and unevenly

- Blowout Danger: Heat builds up in underinflated tires, increasing blowout risk

🔥 Can it blow off?

Not typically, but if the valve stem is severely damaged or incorrectly installed, it can pop out under pressure—causing immediate and dangerous deflation.

🕵️♂️ How to Find and Fix a Clogged Valve Stem

Clogged valve stems are especially common in tubeless tires if sealant is used.

🔍 How to Diagnose:

- Deflate the tire and remove the valve cap.

- Unscrew the valve core using a core tool.

- Try to inflate the tire without the core:

- If air flows: The core is clogged

- If not: The stem is clogged

🧽 How to Fix a Clogged Valve Core or Stem

🧼 If the Valve Core is Clogged:

- Wipe with rubbing alcohol

- Gently remove dried sealant or debris with a plastic pick

- Or simply replace it (they’re cheap)

🧼 If the Valve Stem is Clogged:

- Insert a soft, blunt tool (e.g., small Allen key) to clear blockage

- Avoid sharp tools that can puncture rubber or tire seal

- Reinstall the valve core and check airflow

💡 Prevention Tip: When using sealant in tubeless tires, inflate with the valve at the 5 or 7 o’clock position to avoid sealant clogging the valve.

Find tyre stem repair kit – Amazon

🛞 How to Do This on Tubeless Tires

Tubeless tires are slightly easier to work on since they don’t have inner tubes. But you still must:

- Break the bead (near the valve)

- Install the new stem using a pull-through tool

- Reseat the bead with a strong air burst

🛠️ Tubeless Valve Tip: Always ensure the valve nut is securely fastened (if present), and use tubeless-specific stems with proper sealing gaskets.

🧰 Tools You’ll Need (DIY Valve Stem Repair Kit)

Here’s a quick checklist of tools and items you may need:

- ✅ Valve core remover

- ✅ Valve stem puller or installer tool

- ✅ New rubber or metal valve stems

- ✅ Soapy water for leak testing

- ✅ Air compressor or CO₂ inflator

- ✅ Tire lube (or dish soap)

- ✅ Bead breaker tool or C-clamp

- ✅ Gloves and safety glasses

⚙️ TPMS Warning for Modern Cars

If your car has a TPMS (Tire Pressure Monitoring System), the valve stem may be part of the sensor. Do not attempt DIY replacement without checking:

- Is it a snap-in rubber valve (easy to replace)?

- Or a metal TPMS valve (requires special care)?

Damaging the TPMS sensor can trigger warning lights and cost $50–$150 to replace.

Find tyre stem repair kit – Amazon

🧪 Final Step: Leak Test

After every repair or replacement:

- Mix dish soap and water

- Spray around the valve stem and tire bead

- Look for bubbles—a sign of air escaping

If bubbles form, re-seat or re-tighten the stem.

🏁 Conclusion

A faulty valve stem is a small problem that can turn into a big one if ignored. The good news? With basic tools, a bit of patience, and the right method, you can fix or replace it yourself—even on tubeless tires.

Still unsure about your tire’s condition? Don’t risk a blowout—get it checked or replaced professionally if you’re not confident with the DIY route.

✅ Affiliate Disclosure

As an affiliate, I may earn a small commission from qualifying purchases made through links on this page—at no additional cost to you. This helps me continue providing helpful DIY automotive guides and product reviews. Thank you for your support!

👤 About Me

Hi, I’m Sujith—a mechanical engineering graduate with over 10 years of hands-on experience in product development, food manufacturing, and marketing. I also run a bread-making business and love solving real-world mechanical problems through practical DIY solutions. My blog is dedicated to helping content creators, DIYers, and small business owners find efficient tools, methods, and repairs that actually work.